Testing Facilities

Inspection and Quality Control

- Coordinate Measuring Machines (CMM): These machines are essential for measuring the physical geometries of components with high precision. Our CMM ensures that all dimensions and tolerances are precisely maintained according to the design specifications.

- Micrometers and Calipers: We use these tools for detailed measurements to ensure each part is within the specified tolerances.

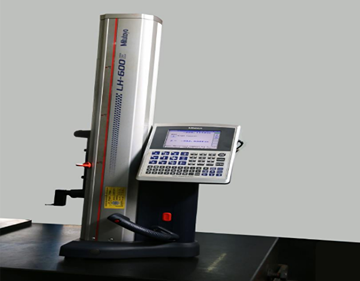

- Surface Roughness Testers: These instruments are used to assess the finish of our parts, ensuring they meet the required surface quality.

- 3D Scanners: For highly complex geometries, we employ 3D scanning technology to inspect the parts and verify their conformity to CAD models.

Every component that leaves our facility undergoes rigorous inspection by our quality control team, ensuring that it meets all design specifications and industry standards.

Comprehensive Production Services

Our manufacturing facility is equipped to handle all aspects of production, from initial design and prototyping to mass production and delivery. We work closely with our clients to ensure that every step of the process is tailored to their specific needs, and we are fully capable of managing both large-scale orders and smaller, custom projects.

- Design and Prototyping: Our team of skilled engineers collaborates with clients to turn their ideas into detailed designs and prototypes. We employ advanced CAD/CAM systems for precise design and programming.

- Material Selection: We source the highest quality materials to ensure the longevity and performance of every component. We offer a variety of materials suitable for each specific application, including metals, alloys, plastics, and composites.

- Mass Production: With our advanced machinery, we can handle large-scale production runs without compromising on the quality or precision of each individual part.

- Post-Manufacturing Processes: Beyond machining, we offer services such as heat treatment, surface coating, assembly, and packaging to meet the complete needs of our customers.

Comprehensive Production Services

Our manufacturing facility is equipped to handle all aspects of production, from initial design and prototyping to mass production and delivery. We work closely with our clients to ensure that every step of the process is tailored to their specific needs, and we are fully capable of managing both large-scale orders and smaller, custom projects.

- Design and Prototyping: Our team of skilled engineers collaborates with clients to turn their ideas into detailed designs and prototypes. We employ advanced CAD/CAM systems for precise design and programming.

- Material Selection: We source the highest quality materials to ensure the longevity and performance of every component. We offer a variety of materials suitable for each specific application, including metals, alloys, plastics, and composites.

- Mass Production: With our advanced machinery, we can handle large-scale production runs without compromising on the quality or precision of each individual part.

- Post-Manufacturing Processes: Beyond machining, we offer services such as heat treatment, surface coating, assembly, and packaging to meet the complete needs of our customers.

We are well-equipped to handle a wide variety of machining processes, ensuring that our components meet the specific needs of each industry. From designing and prototyping to mass production, we offer a comprehensive range of services to create tailored solutions that align with our clients’ unique requirements.

Industries We Serve

- Machine Tool Industry: We provide precision components that are vital for the optimal functioning of machine tools, ensuring durability and performance.

- Automotive Industry: Our automotive components are designed to meet the rigorous standards required for safety and efficiency in vehicles.

- Textile Industry: We manufacture highly durable and precision parts used in textile machinery, enabling smooth production processes.

- Aerospace Industry: Our aerospace components are designed with the utmost precision and adhere to the strictest standards to ensure reliability in high-stakes environments.

- Medical Industry: We provide components that meet the necessary hygiene and precision requirements for medical devices and equipment.

- General Engineering: Our general engineering parts are used in various applications, ensuring optimal performance across different machinery and systems.